Fluid Bed Dryer Industry power dryer/Fluidized Bed Drying Machine/ Laboratory Fluid Bed Dryer/vertical fluid bed dryer Coffee Powder dryer machine/Lab scale Fluidized bed granulator dryer for R&D/ Food Grade Fluidized Bed Dryer

A Reliable Source for High-Quality Fluidized Bed Dryers

Fluidized Bed Dryers are efficient industrial drying systems that use a fluidizing gas to suspend solid particles, ensuring uniform drying. Ideal for pharmaceuticals, food processing, and chemical industries, these dryers offer rapid, energy-efficient drying, preserving product quality. Their versatility and scalability make them a preferred choice for various applications.

At Yatherm Scientific, we give total consideration to efficiency and reliability of drying in your scientific experiments and engineering methods. And that motivates us to provide you state-of-the-art fluidized bed dryers manufactured to deliver phenomenal output and wide range usefulness.

Fluidized Bed Dryer, what is that?

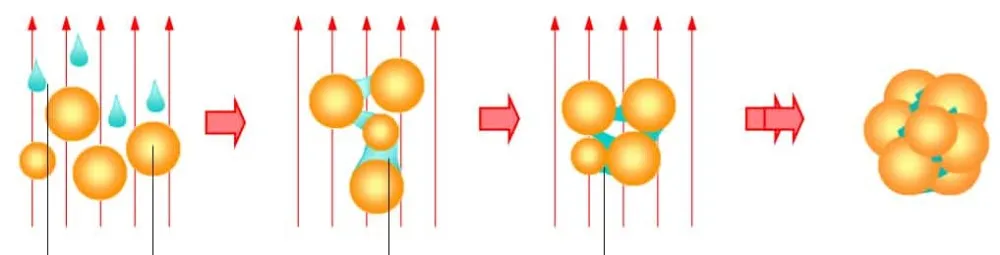

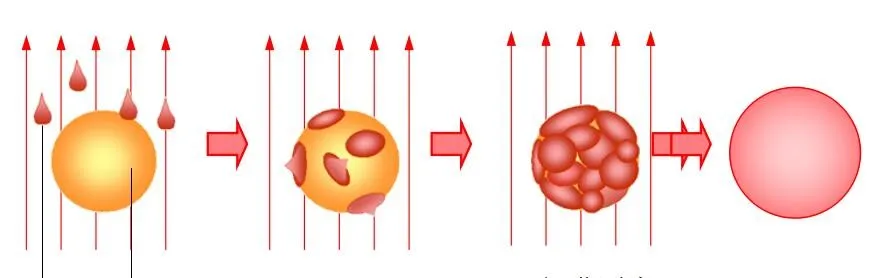

A fluidized bed dryer uses a stream of air to softly elevate the particles generating a bubbling bed for an effective drying process. This facilitates quick and consistent drying throughout the entire batch, making it suitable for high temperature sensitive substances and for tasks that need accuracy in temperature control.

Why Choosing Yatherm’s Fluidized Bed Dryers is Best Deal for You?

● Incomparable performance: Our dryers provide quicker drying durations and top notch product quality, which is not that easily achievable in traditional drying processes.

● Delicate Drying: The fluidized bed process of drying is very gentle in its functioning because it minimizes the thermal stress, which keeps your samples well preserved and their integrity stay intact.

● Accuracy in controlling the temperature: Our dryers helps you meet your drying requirements effectively by precision in temperature control.

● Wide range of Applications: Yatherm's fluidized bed dryers are perfect when it comes to their usefulness. These products can be applicable in various industries and can help in drying many different types of materials.

● Long lasting built: We manufactured our dryers with high-quality materials, they are built to stay functional and useful for a long duration of time, buying our product will be a long time investment for you.

Get These Amazing Benefits by Using a Yatherm Fluidized Bed Dryer:

● Better Quality products: Constant and equally spread drying decreases the chance of samples being deformed because of excessive temperature.

● Improved Process Capability: Quicker drying durations provides you better output and overall productivity in your lab.

● Decreased Costs of operation: Our dryers are manufactured in a way that they consume very less energy. Hence, you will enjoy a decrease in the expenditure of operations.

● Easy to use: Your staff will have no problem handling our dryers because they are easy to operate and work on, requiring very basic training in how to use them.

Technical Specification

| YC-310 Lab Fluid Bed Dryer (300g/batch) | |

| Function | Fluid bed drying, coating, mixing |

| Capacity | Max.300g/batch |

| Minimum material | 100g |

| Rated Airflow | 120 mᶟ/h |

| Peristaltic pump | Max. 1000ml/h |

| Heater power | 3KW |

| Temperature | 40~150 °C |

| Compressed air | 3 Bar |

| Fluid bed drying | Max.300g/batch |

| Mixing | Max.300g/batch |

| Nozzle jet | There are only two nozzles with a fixed diameter, 0.8mm, 1.0mm. |

| Body material | SS 304 stainless steel |

| Dimensions | 700*600*1150mm |

| Display | 4 -7–Inch LCD display |

| PARAMETERS | |||

| YC-1000 Lab Fluid Bed Dryer (1000g/batch) | |||

| Nozzle type | Two fluid nozzle | Voltage | 220V |

| Power | 5KW | Capacity | Max. 1000g/batch |

| Spray dryer capacity | Max. 1500ml/h | Minimum sample volume | 50g |

| granulator temperature | 40-150℃ | Spray dryer inlet temp. | 105-200℃ |

| Compressed air | 2-4 Bar | Temperature precision | ±1℃ |

| Coating | 50-1000g/batch | Mixing | 50-1000g/batch |

| Function | Spray drying, fluid bed drying, coating | Nozzle jet | 0.5/0.8/1.0/1.5/2.0mm optional |

| Airflow | 0-150 mᶟ/h | Peristaltic pump | Max. 1500ml/h |

Main Specifications

|

Model |

YSFBD – 40 |

YSFBD – 80 |

YSFBD – 120 |

YSFBD – 160 |

| Max. capacity(kg) |

40 |

80 |

120 |

160 |

| Temperature of inlet air (℃) |

50-1000 |

50-1000 |

50-1000 |

50-1000 |

|

Pressure of the compressed air (Mpa) |

≥0.4 |

≥0.5 |

≥0.5 |

≥0.5 |

|

Flow rate pf blower (m³/h) |

2062 |

3488 |

3488 |

5153 |

|

Power of the blower(kw/v) |

4/380 |

11/380 |

11/380 |

18.5/380 |

|

Power of the motor for the stirrer (kw/v) |

0.35/380 |

0.55/380 |

0.75/380 |

1/380 |

| Rotary speed of the stirrer (r/m) |

8 |

11 |

11 |

11 |

| Heating method

Steam Pressure (Mpa) Consumption (kg/h) |

≥0.4 120 |

≥0.4 160 |

≥0.4 160 |

≥0.4 160 |

| Heating method

Electricity(kw) |

15 |

30 |

40 |

60 |

| Height of the main machine (mm) |

1800 |

2300 |

2800 |

3200 |

Applications

The dryer is used to dry granular materials in food, chemical, and other industries. The briefly as follows, through the heating of air high-speed draught is formed by the gas distribution board to make the material in question boil, thereby dispelling the moist draught and achieving the goal of drying. This dryer is composed of dryer air filter, air heater, draught fan and automatic temperature controller.

Principle

Principle

- Fast, uniform and High drying speed

- Hermetic, Nonpolluted and Temperature draught after being filtered

- User friendly operation with low maintenance

- Easy cleaning

- Meeting GMP Standard

Top fluid bed drying

Bottom- fluid bed coating.

How to choose proper machine / equipment :

- What is the size , shape and output requirement?

- What is the production capacity?

- How much kilogram per hour or per day?

- What is your power supply , Load and frequency?

- What is your production line and workshop design?

Buy A Yatherm’s Fluidized Bed Dryer Now!

Take your drying process to the next level with Yatherm Scientific’s top quality Fluidized bed dryers, which are perfect in all areas. If you are seeking a dependable, high throughput and multi-functional drying method, you are at right place.

Contact us now so that you will learn more about our versatile products and let us help you in achieving your best drying goals in your experiments and overall growth of your business!

Quotation Request Form